Testing can be done based on international or national standards and regulations, as well as tailored to customer requirements (customized testing), both for the purpose of certification as well as during product development e.g. performance testing of a product, comparative testing of multiple different brands for suitability or customized safety testing to evaluate safety behavior in more detail than what is done in the framework of standard-based testing.

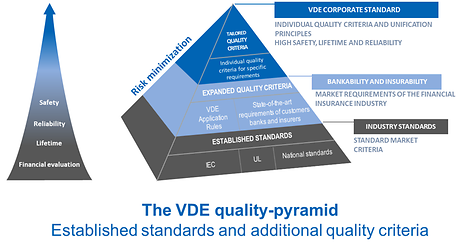

In the area of PV Modules and Components, and Battery Energy Storage, we work with many of the leading international manufacturers to certify conformance with a variety of IEC, UN (Batteries only), and VDE, as well as conduct testing based on other standards (e.g., UL).

VDE works with multiple state-of-the-art testing facilities throughout the world, including test labs in Germany, US, and China. The focus of our testing operations has been in the areas of product safety and reliability. These resources enable us to support our customers more effectively and efficiently.

The VDE Quality Tested mark for PV Modules features a stringent and optimized testing program tailored to achieving technical bankability. The quality standard of the VDE Quality Tested mark for PV modules offers distinct advantages in:

- Superior level of consistent quality

- Increased safety

- Low power degradation

- Lower risk for return on investment

- Strong support for technical bankability

This allows firms to request testing for their products that exceed the basic tests that are part of the industry standard, and be tested according to expanded quality test criteria, or even tailored criteria as with the VDE Corporate Standard.