With its cutting edge test laboratory and long-time expertise in the field of service life tests, especially for electronic components, VDE Institute offers manufacturers and users a wide range of reliability test.

The benefits for you:

- Early detection of weak spots

- Quick reliability information thanks to statistical predictions

- Reduced consequential costs

- Enhanced level of quality

DIN EN 62059-31-1:2009-07 (IEC 62059-31-1)

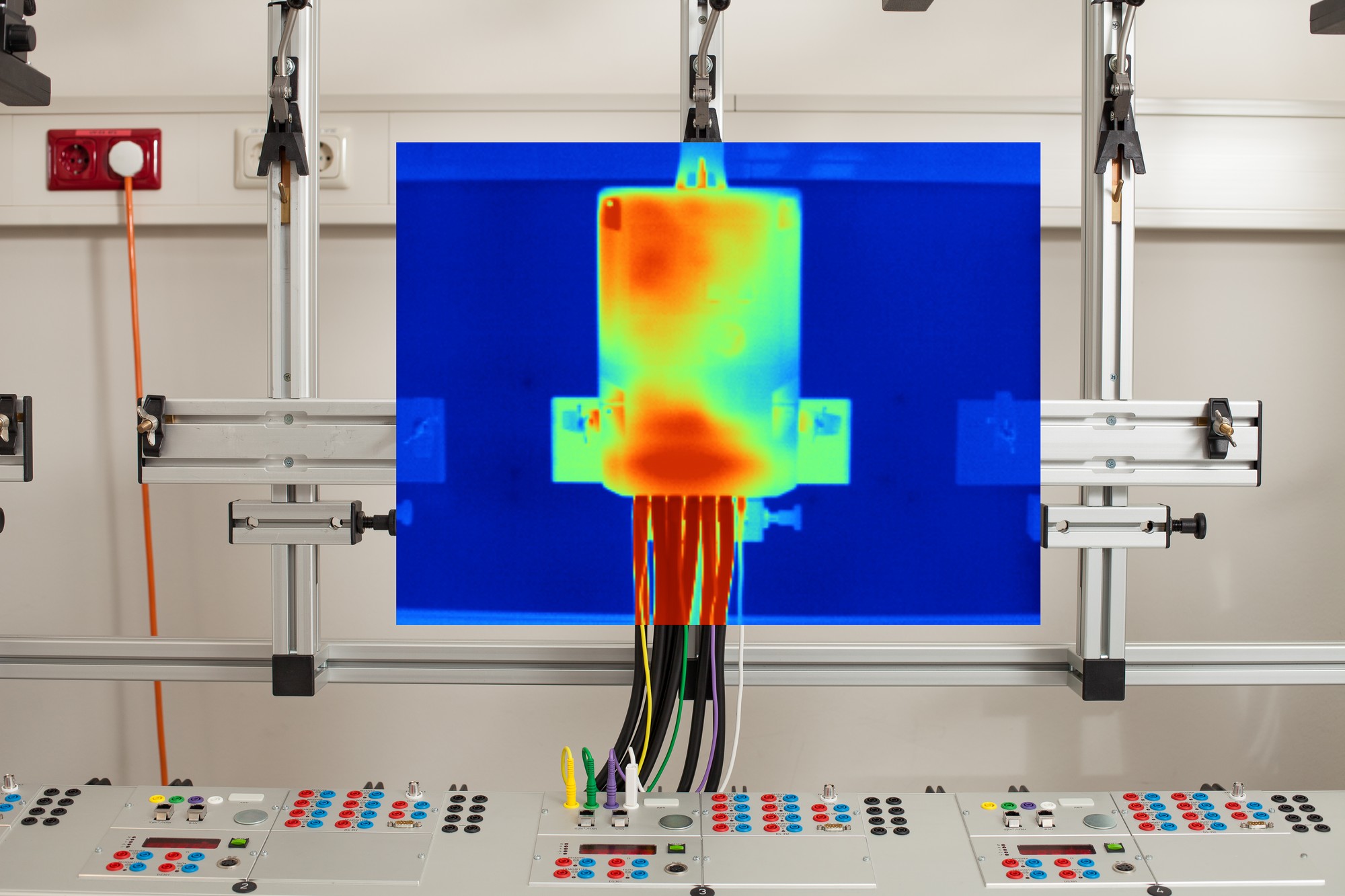

In this accelerated reliability test, random samples are subjected to stress levels exceeding the intended operating conditions. The goal is to shorten the elapsed time until product failure, without subjecting them to new failure mechanisms.

The service life is assessed through record entries and examinations of the failures during the test. By determining the failure distribution and calculating service life models, it is possible to extrapolate the time to failure under the intended operating conditions. This process delivers quantitative results with its confidence limits and may be used to compare service life parameters of products that originate from different suppliers or from different lots of the same manufacturer.

DIN EN 62059-32-1:2012-10 (IEC 62059-32-1)

This draft standard represents the basis for assessing the metrological characteristics of an electricity meter under increased loads. The meter is operated for a longer period of time at the upper limits of operating temperature, voltage and current.

The change in the percentage measuring error of the test object at the beginning and at the end of the test serves as the acceptance criterion.

The VDE Institute also offers tailor-made tests such as climatic storage at elevated ambient temperature and humidity. Take advantage of our state-of-the-art meter testing equipment, which records changes in metrological characteristics under heightened climatic conditions.

Benefit from our experience in the field of statutory measuring to verify that your product meets increased reliability standards and measurement stability.

DIN EN 62059-41: 2007-01 (IEC 62059-41)

This standard provides methods for predicting the failure rate of electricity meters, which are assumed to be constant, based on the component stress process.

The result of the prediction can be used in the development phase to safeguard development decisions, relating to the type approval for safeguarding decisions regarding the certification period and in the operational phase to determine the required scope of maintenance to preserve the required availability.