Solar glass fracture is a probabilistic event that occurs based on a combination of internal and external factors, many of which are hiding in plain sight.

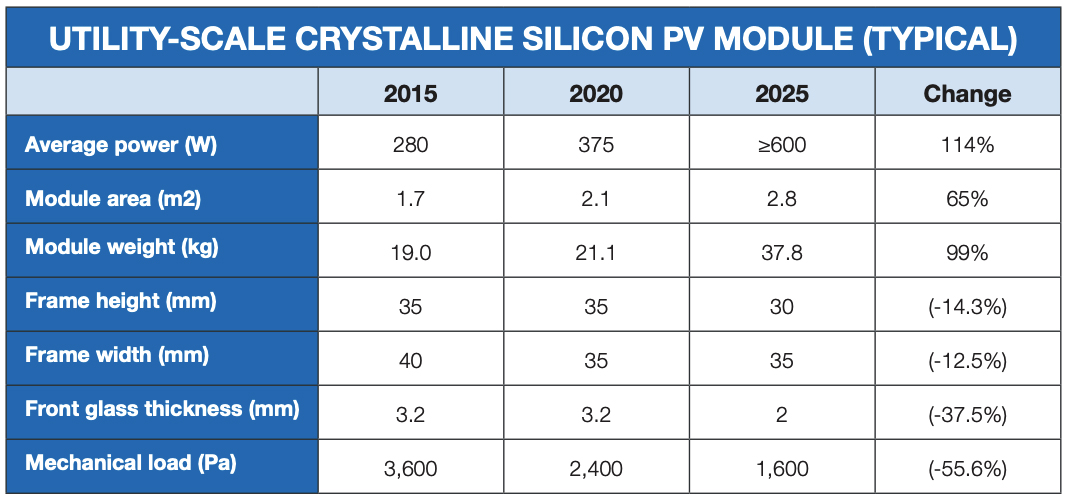

As an example, module manufacturers have largely continued to treat solar glass as a commodity—meaning it is rarely subject to batch traceability or lot tracking—even though tempering process control becomes more important as modules get bigger, as shown in Figure 6. Meanwhile, forensic analysis has revealed evidence that glass supply chain plays at least some role in the proliferation of low-energy glass fracture.

“A developer came to RETC recently with two side-by-side projects,” recounts Kedir. “While both sites used modules from the same manufacturer, the number of cracks exhibited on one site was an order of magnitude higher than the other. Testing modules from the site experiencing glass failure, we found that 75% of samples tested under the design load rating. It turned out that the modules at these side-by-side sites came from two different production lines, each supplied by a different glass manufacturer.”

If a change in glass vendor at the point of production can account for an order of magnitude difference in early mortality in the field, why isn’t this variable part of a standard bill of materials (BOM) verification process? From my perspective as a technical advisor who helps de-risk large utility-scale solar projects, identifying and procuring resilient BOMs requires traceability, transparency and data. After all, that is one of the main ways independent engineers, owner’s engineers and consulting engineers ensure fielded projects can withstand site-specific conditions of use while optimising investor returns.

Given that collective action is required to prevent today’s infant mortality issues from stymying tomorrow’s growth, the role of the industry’s technical due diligence community is more important than ever. Reliability engineers have a responsibility to help module and tracker companies make fielded systems as inexpensive as possible, but not so cheap that upfront cost savings drive up operational expenses.

Scientific researchers and testing laboratories have a responsibility to help industry stakeholders identify the root causes of low-energy glass fracture and develop new test sequences that screen for field-observed failure modes. Technical advisors have a responsibility to demand better data than vague module datasheet glass descriptors such as “semi-tempered”, “half-tempered”, or “heat treated”.

Further downstream, system developers, owners and operators, and EPC firms have a responsibility to make scienceand engineering-based decisions regarding product procurement and deployment. Last but not least, project financiers and insurers have a responsibility to raise the minimum bar for bankability and provide differentiated terms and conditions for projects that meet or exceed these best practices.

References

[1] Silverman, T., et al, 2024, “Tough Break: Many Factors Make Glass Breakage More Likely,” National Renewable Energy Laboratory, Technical Report, NREL/TP-5K00-91695.

[2] Braga, M., et. al, 2023, “Investigating the causes and consequences of glass cracks on double-glass large area bifacial PV modules,” NREL PV Reliability Workshop, Poster Presentation.

[3] Wang, D., 2024, “Wind speed and rear glass breakage on bifacial PV module mounted on trackers,” DNV white paper.

[4] Solar Energy Technologies Office, “2020 Utility-Scale Solar Goal Achieved,” U.S. Department of Energy, Online, September 12, 2017.

[5] IRENA, 2020, “Renewable Power Generation Costs in 2019,” International Renewable Energy Agency, Abu Dabi.

[6] Lazard, “2025 Levelized Cost of Energy+,” June 2025.

[7] IEA, 2024, “Best Practices for the Optimization of Bifacial Photovoltaic Tracking Systems Bifacial,” International Energy Agency Photovoltaic Power Systems Programme Technical Collaboration Program (IEC PVPS TCP).

[8] Palmiotti, E., et al, 2025, “Growing Panes: Investigating the PV Technology Trends Behind Frequent Early Failures in Modern Glass–Glass Modules,” IEEE Journal of Photovoltaics, Vol. 15, No. 2.

[9] Markert, J., et al, 2025, “What Can We Learn from the Comparison of Glass Breakage between Lab and Field,” Franhoffer ISE, SOPHIA Workshop 2025.

[10] RETC, “2025 PV Module Index Report,” Renewable Energy Test Center, June 2025.

About the Author